From Chemical Plants to Cloud Platforms: My Unconventional Ascension into the World of Business Applications

- October 24, 2025

- Posted by: Cyrille Nembot

- Category: Cyrille Nembot

For twelve years, my professional identity was built on a foundation of tangible things. As a Chartered Chemical Engineer and Project Manager, I dealt with steel, catalysts, pressure vessels, and complex contracts. My world was one of process flow diagrams, Gantt charts, and commissioning plans. The transition to the seemingly abstract world of Dynamics 365 (D365) felt, at first, like leaving solid ground for a cloud—literally.

Yet, what I discovered was that my journey through engineering and project management hadn’t just given me a set of skills; it had given me a specific way of thinking. This mindset, more than any specific line of code, became the compass that guided my successful navigation into the D365 ecosystem.

The Landscape: From Process Flows to Data Flows

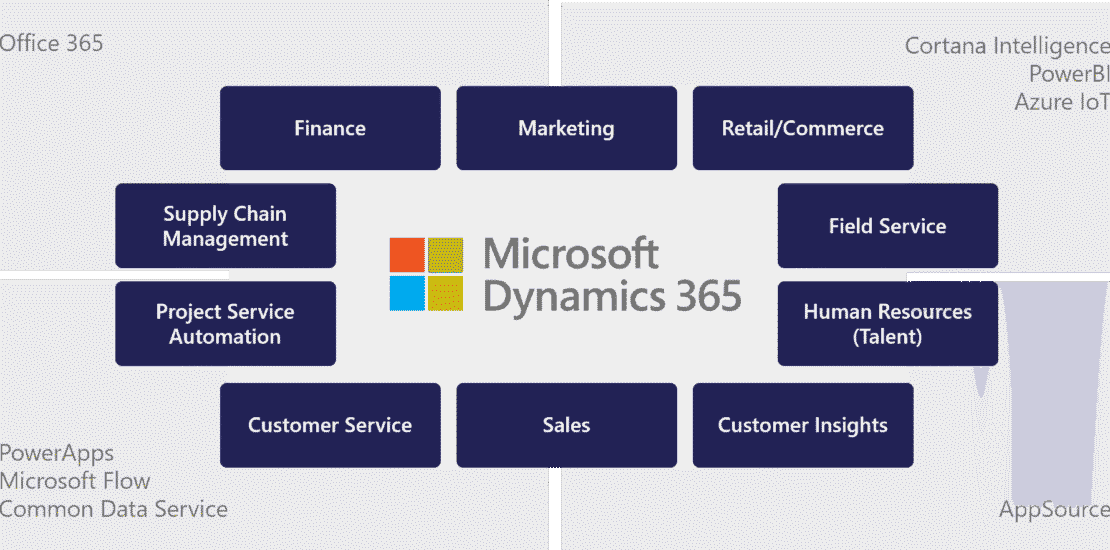

The field of business applications, at its core, is about creating digital reflections of business reality. D365 Finance & Operations, for instance, is not just software; it’s a virtual factory. It manages the flow of materials (supply chain), the conversion of raw materials to finished goods (production orders), and the financial energy that powers it all (general ledger).

This was my “aha!” moment. The challenge wasn’t learning a new industry; it was recognizing that I was already fluent in its language. The “overwhelming technology stack” was just a new set of unit operations. The “abstract concepts” were simply digital twins of the physical processes I already knew.

The Challenges: My Personal Valley of Transition

My challenges were specific and deeply felt:

- The Imposter Syndrome of “Soft” Skills: Coming from a world where success was measured in on-time, on-budget project delivery and functional specifications, the intangibility of software was daunting. How could I prove my worth without a physical plant to show for it?

- The Vocabulary Shift: I was fluent in P&IDs (Piping and Instrumentation Diagrams), but now I had to master ERDs (Entity Relationship Diagrams). My “bill of materials” was now a “product master.” The concepts were parallel, but the lexicon was foreign.

- The Depth of the Ecosystem: D365 is not one application but a suite. Focusing on Finance & Operations felt like specializing in a single, massive distillation column within a vast chemical complex. The scale was intimidating.

The Secret Weapon: My Transferable Skills in Action

This is where my past stopped being a former life and started being my greatest asset. My “transferable skills” weren’t just bullet points on a resume; they were my day-to-day tools.

1. The Chemical Engineer’s Mindset: Systems Thinking

- The Skill: As an engineer, you never look at a valve in isolation. You understand its impact on upstream pressure, downstream flow, and the entire system’s stability.

- The D365 Application: When a client asks to “add a new field to the sales order,” my engineer’s brain doesn’t just add the field. I ask: Where does this data originate? (The upstream source). Which other processes need it? (Inventory allocation, shipping, invoicing). How does it affect reporting and the general ledger? (The downstream impact). This prevents creating siloed data and “band-aid” solutions that break the wider system. I wasn’t just configuring a screen; I was ensuring data integrity across the entire business process.

2. The Project Manager’s Discipline: Orchestrating Complexity

- The Skill: Managing a multi-million dollar project teaches you that chaos is the default state. Success comes from rigorous scope management, stakeholder communication, and a relentless focus on the critical path.

- The D365 Application: Implementing D365 is a project. My 12 years of experience became my guide. I instinctively:

- Define the “Project Charter”: What is the business problem we are solving? (e.g., “Reduce order-to-cash cycle time by 20%”). This becomes our North Star.

- Manage Stakeholders: I knew how to talk to the Finance Director about ROI, the Warehouse Manager about pick/pack efficiency, and the IT Director about data migration and security. I was the translator, a role I’d perfected managing contractors, clients, and engineers.

- Mitigate Risks: A project manager is always asking, “What could go wrong?” This mindset is perfect for identifying gaps in requirements, potential user adoption issues, and data migration risks before they derail the go-live.

3. The Sales & Contract Manager’s Acumen: Understanding the “Why”

- The Skill: Negotiating contracts and managing sales taught me that every business process exists to serve a commercial outcome. It’s about risk, reward, and relationship.

- The D365 Application: This background gave me an innate understanding of the core business domains within D365.

- When configuring the Sales module, I wasn’t just following a spec; I was recreating the nuanced stages of a deal I had lived through a hundred times—from lead qualification to contract signing.

- When working on the Procurement module, I understood the criticality of terms and conditions, three-way matching (PO, GRN, Invoice), because I had seen the financial and legal risks of getting it wrong.

The Mindset: The Bearings on My Compass

My journey was guided by three core attitudes, forged in my previous career.

- The Architect Mindset (from the Engineer): I am not a configurer; I am a designer of systems. My goal is to build a D365 solution that is robust, scalable, and elegant—just like the chemical plants I used to help commission.

- The Explorer Mindset (from the Project Manager): No two projects are the same. I learned to be comfortable with the unknown. Now, I channel that into relentless learning through Microsoft Learn, community forums, and hands-on experimentation in my own sandbox environment. The technology changes, but the discipline of learning remains.

- The Translator Mindset (from the Sales & Engineering Bridge): This is my superpower. I can sit with a supply chain manager, understand their pain points with inventory inaccuracy, and translate that into a technical design for cycle counting, warehouse management, and integration with the production module. I speak both “Business” and “Tech” because I’ve been a native speaker of both.

A Practical Roadmap, Informed by Experience

My path wasn’t linear, but it was deliberate:

- I Chose My “Unit Operation”: I focused on D365 Finance & Supply Chain Management because it mirrored my existing knowledge. I didn’t try to become an expert in CRM; I doubled down on my domain strength.

- I Got Certified with Context: I pursued the MB-300 and MB-330 certifications. But I didn’t just memorize. I constantly related every module, every feature, back to a real-world project or business challenge I had faced. The exam was a checkpoint; the understanding was the goal.

- I Built My “Portfolio Plant”: I used a demo environment to model a simple end-to-end process I knew intimately from my engineering days: procuring a raw material, receiving it into inventory, and consuming it in a production order. This practical, tangible project was my proof of concept—to myself and to future employers.

Conclusion

My transition from Chemical Engineering to D365 was not an abandonment of my past, but an evolution of it. The challenges were real, but the bearings I had—systems thinking, project discipline, and commercial acumen—proved to be the most reliable navigation tools I could have had.

Your unique background is not a barrier; it is your differentiator. The world of business applications desperately needs people who don’t just see configuration options, but who see the business processes, risks, and opportunities they represent. Your journey has already equipped you with the hardest skills to teach: how to think. The software? That’s just the new set of valves and controls you’ll learn to master.